Welded Square Steel Pipe Specification

• Name: Welded Square Steel Pipe

• Standard: ASTM A106, ASTM A53, BS1387, EN 10217, EN 10219, EN10035, JIS G3444, JIS G3452

• Grade:GR.A, GR.B, GR.1-GR.3, Q195-Q345, C250, C350, C250L0, STK500, S235JOH-S355JOH, S235GT

• Types: Mechanical Pipe, Tubing and Casing, Roller Pipe, Drilling Pipe, Structural Applications

• Out diameter: 10x10--150x50mm

• Thickness:0.5mm ~8mm

• Length: 0.5-12M

• Pipe Coating: Oiling, Lacquering, Hot-Dip Galvanizing, Powder Painted, Electro-Galvanized

• Pipe End Type: Square End, Bevelled End, Threaded End, Grooved End, Shouldered End

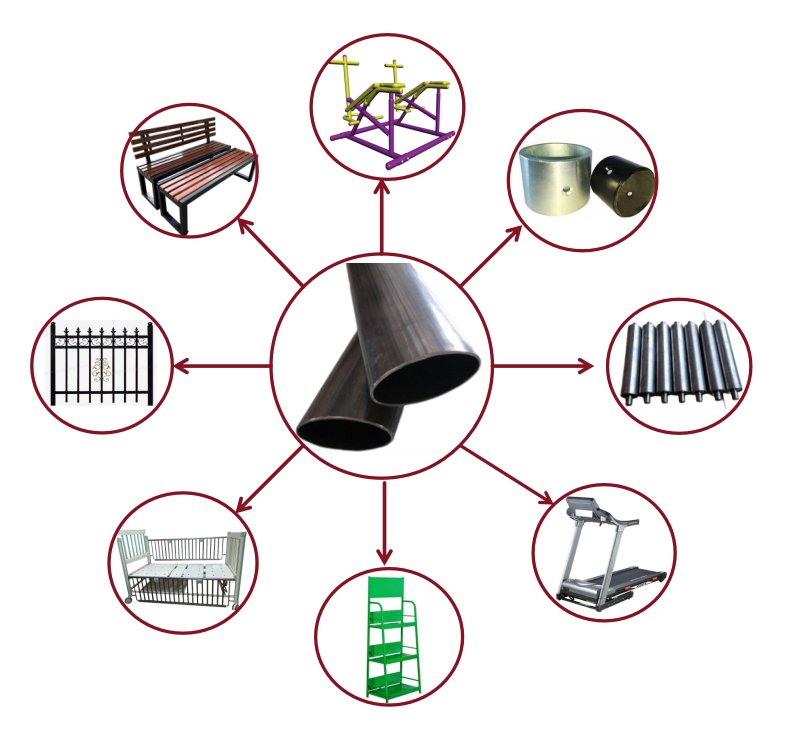

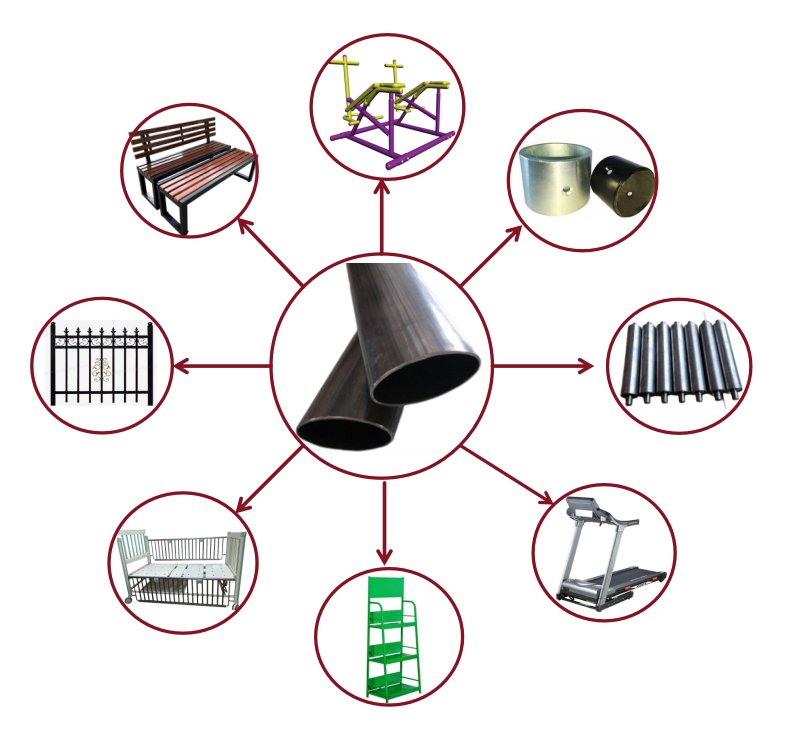

Welded Steel Pipe Application

Production Arrangement and Customer Service

Given that we have sufficient raw material and tube stocks, our production line is fully operational and can meet the market's growing demand for welded rectangular steel pipes. We are committed to providing prompt delivery and high - quality products to all our clients.

• Order Processing

Expedited Production: We've allocated additional shifts to our production lines. As a result, we can now handle large - scale orders within a short lead time of just 7 - 10 days.

Customization Options: We offer customized cutting and finishing services for our standard stock. This allows us to precisely meet the specific requirements of each project.

• Quality Assurance

Rigorous Testing: Every batch of raw materials undergoes thorough testing. We check for mechanical properties, dimensional accuracy, and weld integrity to ensure that only the highest - quality products are delivered.

Certifications: Our production processes strictly adhere to international standards such as ASTM, EN, and DIN. This guarantees the reliability and consistency of our products.

• Customer Support

Dedicated Account Managers: Each customer will be assigned a dedicated account manager. They will be available to provide personalized support throughout the order process.

Inventory Updates: We offer real - time inventory tracking and regular updates on order status. This helps our customers stay informed and plan their projects effectively.