Types Of Galvanized Steel Tube

• Square Galvanized Steel Tube

Square tube,it provides good stability in both horizontal and vertical directions, and is not easy to deform under pressure.The flat surface is convenient for cutting, bending, welding and other processing operations, and is easy to connect with other components.

• Rectangular Galvanized Steel Tube

Rectangular tubes are often used in mechanical, structural, and construction work, just like square hollow sections. The pipe’s flat surface is more cost-effective for joining and other fabrication work.

• Circular Galvanized Steel Tube

Round tube is made by rolling a flat steel sheet into a circular shape at a certain radius and then welding the seam. Widely used in construction Industry, parts and other fields. It is often used in the production of furniture such as tables, chairs, and beds to make legs and frames.

Specifications Of Galvanized Steel Tube

The pipe manufacturing process makes a galvanized steel tube. It is strong enough to ensure the structure’s integrity. The production standards are strictly followed in manufacturing. It is available in different steel grades as well. These galvanized steel tubes are highly efficient and are used in various engineering and construction applications.

| NAME | Galvanized Steel Tube |

| Standard | API, ASTM, BS, EN, JIS, DIN… |

| Shape | Round, Square, Rectangular |

| Steel Material | Carbon steel, Alloy steel |

| Length | 1-12m or customized |

| Wall Thickness | 1mm -8mm or customized |

| Tolerance | As per different standard |

| Manufacturing Process | ERW |

| Pipe Ends | Plain End, Beveled End, Threaded, Grooved |

| Pipe Surface | Varnishing, Oiling, Hot Dip Galvanizing, Pre Galvanized, Powder Coated |

| Joint Method | Fitting, Joiner, Clamp, Pipe Shoulder, Welding,Thread |

| Application | Structure, Construction, Mechanical, Fitness Equipment and Water transport, Mining, Steel Furniture, Green House… |

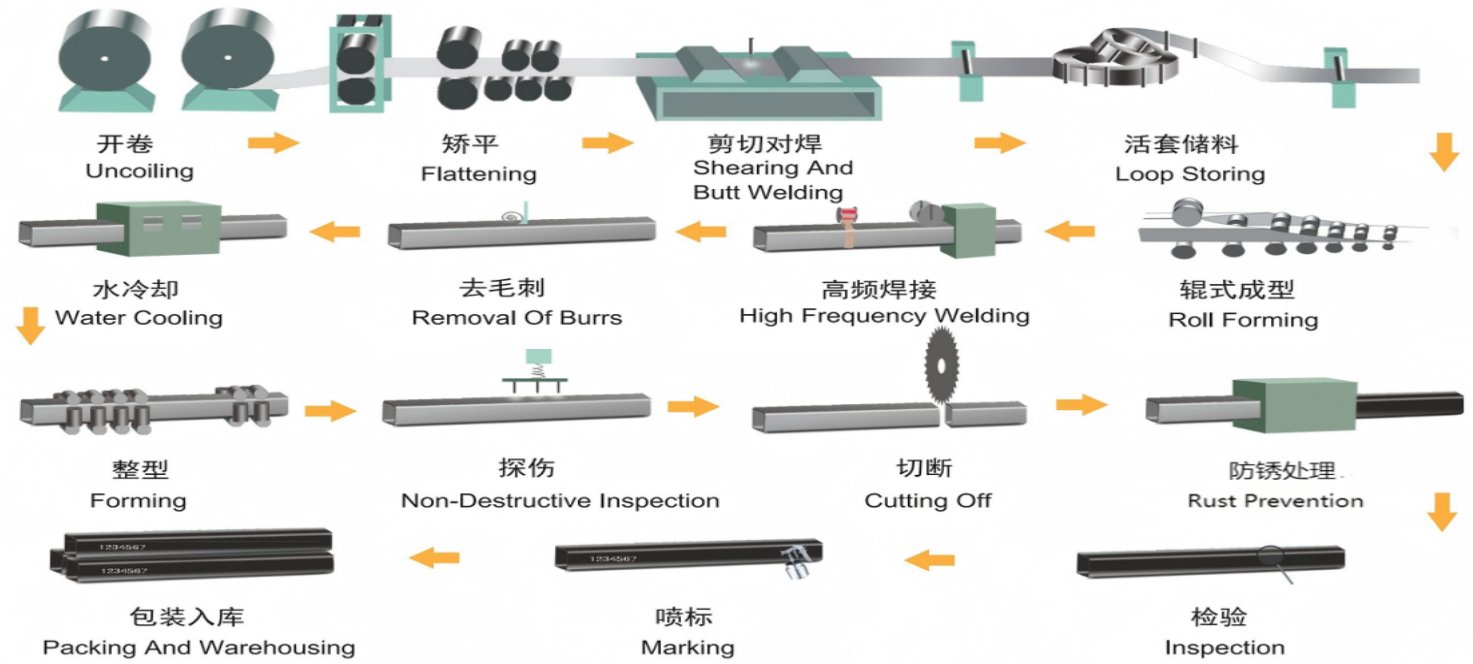

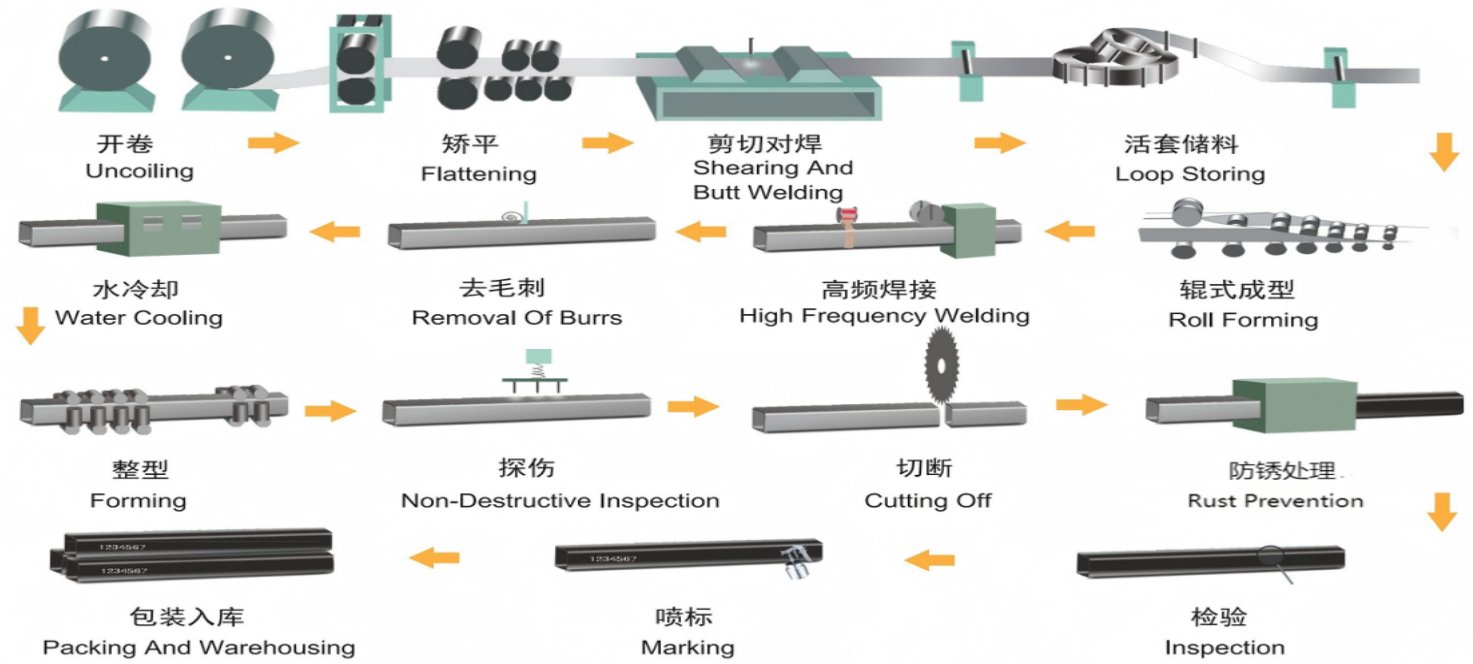

Hollow Section Manufacturing Process

Galvanized Steel Tube Applications

Construction Industry: In the construction industry,galvanized tubes are widely used in the construction of building frameworks, such as in the scaffolding systems to provide stable support.

Mechanical Manufacturing: It is used to make mechanical parts such as shafts and hydraulic cylinders.

Transportation Industry: In the construction of vehicles and ships, CHS is used for making frames, guardrails, and some supporting structures.

Furniture Manufacturing: Galvanized tubes are used to make some decorative frames, railings, and furniture legs. Their good appearance can meet the needs of both aesthetics and practicality.

Pre Galvanized Tube Vs. Hot Dipped Galvanized Tube

| Pre Galvanized Tube | Hot Dipped Galvanized Tube |

| It's made by galvanizied strips or coils | Made tube first,then do hot-dip galvanizing process |

| Thickness of the zinc coating is relatively thin | Thicker zinc coating and a dense zinc-iron alloy layer |

| The surface is smooth with a relatively uniform color | The surface has a slightly rough compared to pre-galvanized tubes |

| Their corrosion resistance is relatively limited | Excellent corrosion resistance and long service life |

| Often used in some indoor environments | Widely used in outdoor construction projects |