ERW Round Steel Pipe Specification

• Name: ERW Round Steel Pipe

• Standard: ASTM A106, ASTM A53, BS1387, EN 10217, EN 10219, EN10035, JIS G3444, JIS G3452

• Grade:GR.A, GR.B, GR.1-GR.3, Q195-Q345, C250, C350, C250L0, STK500, S235JOH-S355JOH, S235GT

• Types: Mechanical Pipe, Tubing and Casing, Roller Pipe, Drilling Pipe, Structural Applications

• Out diameter: 10-170mm

• Thickness:0.5mm ~8mm

• Length: 0.5-12M

• Pipe Coating: Oiling, Lacquering, Hot-Dip Galvanizing, Powder Painted, Electro-Galvanized

• Pipe End Type: Square End, Bevelled End, Threaded End, Grooved End, Shouldered End

Application Of Carbon Steel ERW Round Pipe

| Structural Purpose ERW steel pipes are used as structural members, such as in the construction of scaffolds, steel frameworks of buildings,bridges and steel furniture.They provide good strength and stability. |

| Fitness Equipment ERW steel pipes have high strength and good toughness, being able to withstand large forces during fitness exercises. They are often used in the main frames of fitness equipment like treadmills and weightlifting racks. |

| Building Structure Due to its flexibility, versatility and toughness,low carbon steel pipe can withstand extreme temperatures and pressures.It is widely used in building support columns, building frames,with a zinc coating that provides corrosion resistance and a long service life of 40 to 50 years. |

| Steel Fence ERW steel pipes are easy to cut, bend and connect, which can be processed and installed according to the actual needs of the site.The surface of ERW steel pipe can be galvanized and other anti-corrosion treatment, which can be used outdoors for a long time without being easily corroded and prolongs the service life of the steel fence. |

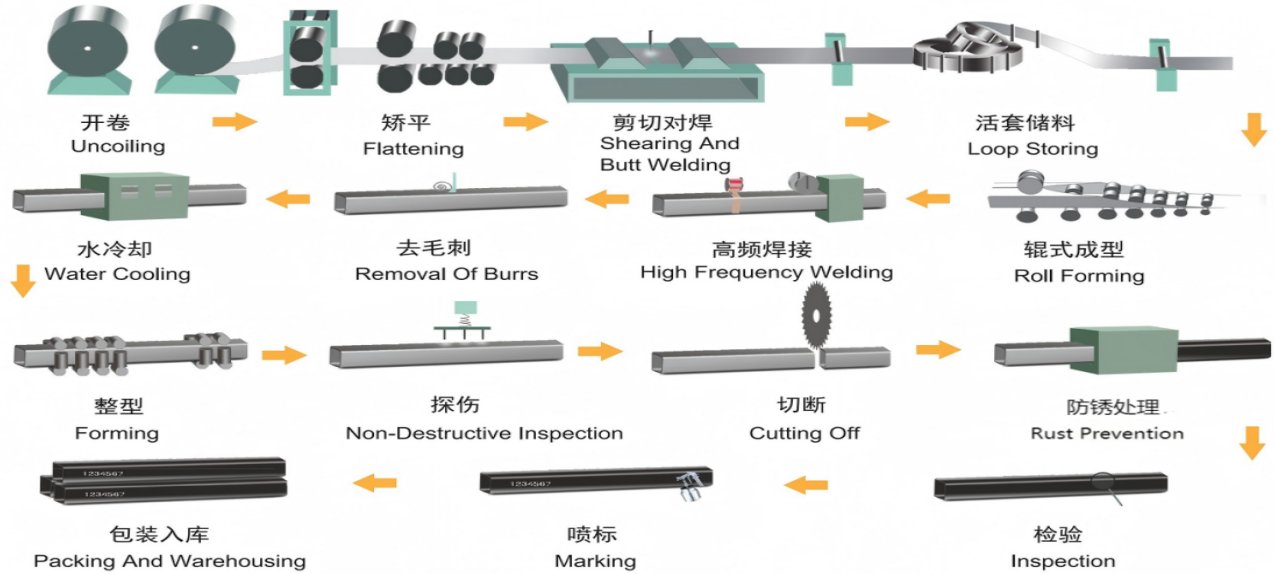

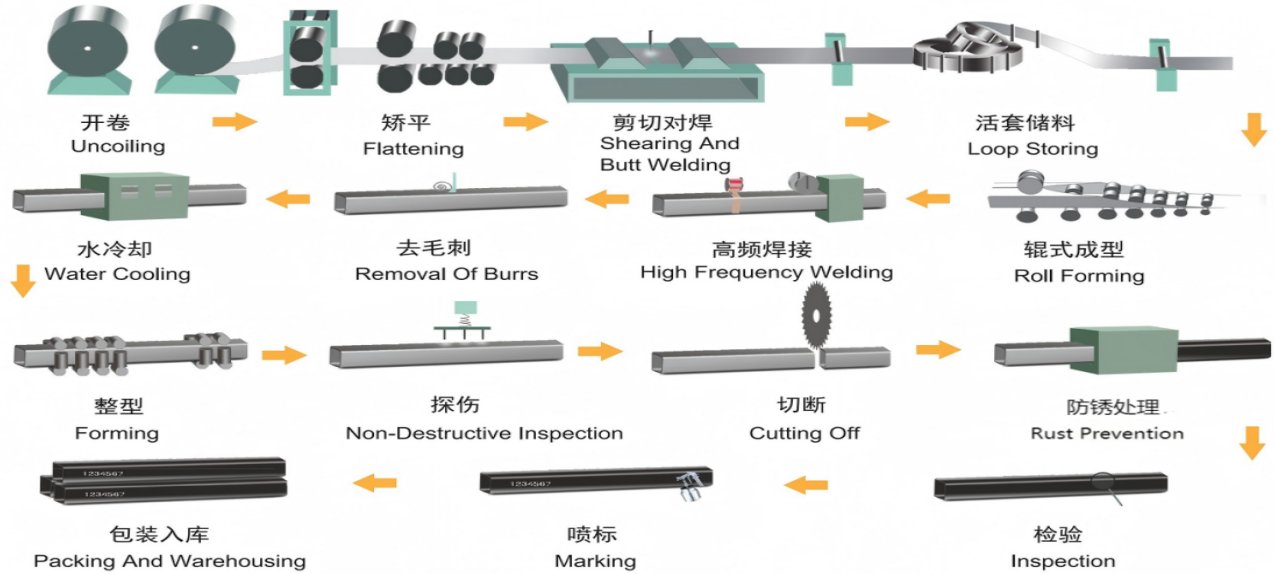

ERW Steel Pipe Manufacturing Process

Welded Pipe VS. Seamless

Welded pipes are generally more cost-effective to produce. The manufacturing process of welded pipes is relatively simple. They are made by bending a steel plate or strip into a tubular shape and then welding the seam, which requires less complex equipment and technology, resulting in lower production costs. Due to the lower manufacturing cost, welded pipes are usually cheaper in the market. For projects with a large demand for pipes but not extremely high requirements for pipe performance, using welded pipes can significantly reduce material costs.

| Welded Pipe | Seamless Pipe |

| Cheaper option compared to seamless pipes | Expensive than welded pipe |

| It has welding seam on tube | No welding seam on the tube |

| The main raw material is steel coils and strips | Made of solid round bars |

| High production efficiency | With high OD and ID tolerance |

| Thickness tolerance is moderately precise. | Can bear high-pressure |

| Used for low/medium pressure applications | Thickness tolerance is stable and accurate |