Steel Pipe for Rollers

• Name: Steel Pipe for Rollers

• Standard: ASTM A106, ASTM A53, ASTM A179,DIN2391, EN10216,JISG3454, JISG3441 etc.

• Grade: GR.A, GR.B, GR. C, 10#, 20#, 35#, 45#, STK 500, STK540,STK 500, SPTG370,STPG410,STS370,STS410.STS480,1008,1020,1013,4140,5130 etc

• Types: Engineering Pipe, Tubing and Casing, Roller Pipe, Drilling Pipe, Automobile pipe, etc

• Out diameter: 10-120mm

• Thickness:0.5mm ~20mm

• Length: 0.5-12M

• Pipe Coating: Oiling, Lacquering, Hot-Dip Galvanizing, Powder Painted, Electro-Galvanized

• Pipe End Type: Square End, Bevelled End, Threaded End, Grooved End, Shouldered End

Supply Condition

• Cold drawn / hard (+C) No heat treatment after last cold forming process.

• Cold drawn / soft After last heat treatment there is a light finishing pass (cold drawing)

• Cold drawn (+SR) After the final cold forming process the tubes are stress relieve annealed.

• GBK (+A) After the final cold forming process the tubes are annealed in a controlled atmosphere.

• NBK (+N) After the final cold forming process the tubes are annealed above the upper transformation point in acontrolled atmosphere.

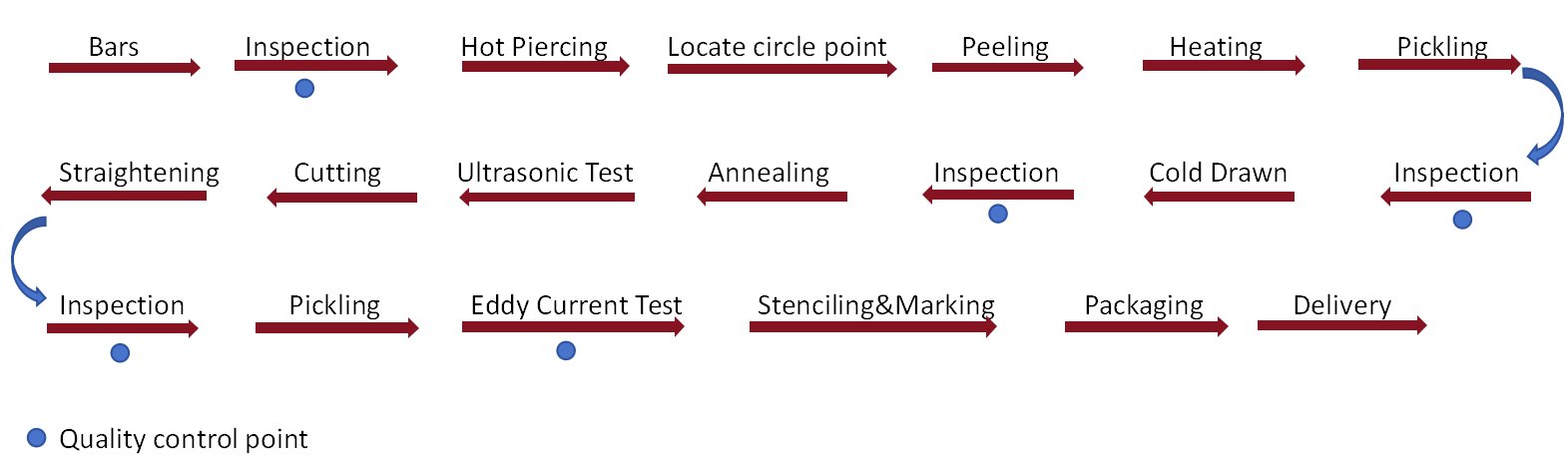

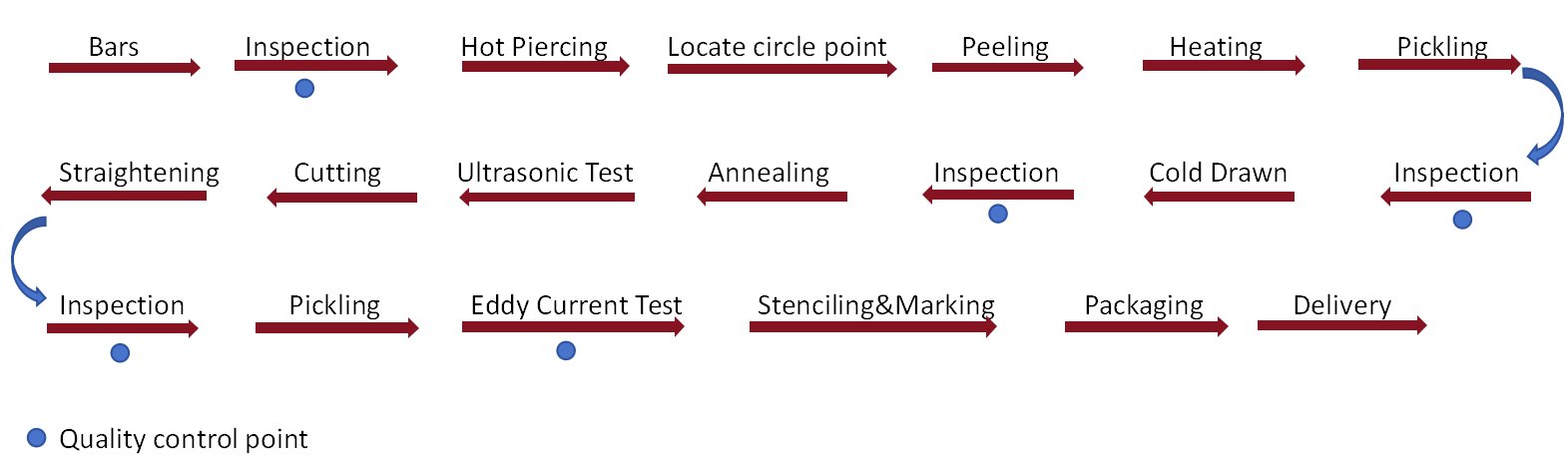

Seamless Steel Pipe Manufacturing Process

The round steel bar is used to produce seamless pipe. After heating the bar to a high temperature, a probe is put into the bar to produce a hole. The cylinder is then moved to rollers that shape it to the required diameter and wall thickness.

Why Choose HAOTAN?

• Precise custom outer diameter and inner diameter

• Tight tolerances, resulting in reduced machine time / Dimensional accuracy

• Eddy current inspection and ultrasonic inspection

• Smooth and Clean OD and ID surfaces

• Excellent machining characteristics

• Wider range of physical properties attainable through process and annealing options

• Our products were exported to Europe, America, Japan, South Korea, The Middle East, Southeast Asia and in total six continents over 20 countries, and which has been consistently trusted by customers.

• The annual production capacity can reach 60,000 tons under years of development. Every-year R&D investment and a team of technicians enable strong R&D capability. HAOTAN has full system of production with advanced equipment, such as perforation, pickling, cold rolling, cold drawing, straightening, flaw detection, tensile test and machining.