EN10305-1 Tube Specifications

• Procedure: SMLS

• Dimensions: 10.3mm – 165mm

• Thickness: 1.0mm – 25mm

• Unit Length: 1 – 12 metres

• Steel Grade: E215,E235,E355

• End Shape: Beveled end, plain end, vanished, or adding plastic caps, as per customer's requirements

• Pipe Packing: In bundles, Plastic film full length wrap

Supply Condition

• Cold drawn / hard (+C)

• Cold drawn / soft

• Cold drawn (+SR)

• GBK (+A)

• NBK (+N)

Chemical Composition(%)

| Steel Grade | C | Si | Mn | S | P | Al |

| Steel name | Max. | Max. | Max. | Max. | Max. | Max. |

| E215 | ≤0.10 | ≤0.05 | ≤0.7 | ≤0.025 | ≤0.025 | ≤0.025 |

| E235 | ≤0.17 | ≤0.35 | ≤1.20 | ≤0.025 | ≤0.025 |

|

| E355 | ≤0.22 | ≤0.55 | ≤1.60 | ≤0.025 | ≤0.025 |

|

| Elements not included in this Table (but see footnote c) shall not be intentionally added to the steel without the agreementof the purchaser, except for elements which may be added for finishing the cast. All appropriate measures shall be taken toprevent the addition of undesirable elements from scrap or other materials used in the steel making process. |

Mechanical Property

| Steel grade | SR | A | N |

| Yield | Tensile | Elongation | Yield | Elongation | Yield | Tensile |

| Strength | Strength | rate | Strength | rate | Strength | Strength | rate |

| Steel name | Steel number | (Reh mpa) | (Rm mpa) | A% | (Reh mpa) | A% | (Reh mpa) | (Rm mpa) | A% |

| E215 | 1.0212 | 380 | 280 | 16 | 380 | 30 | 290 to 430 | 215 | 30 |

| E235 | 1.0308 | 420 | 350 | 16 | 420 | 25 | 340 to 480 | 235 | 25 |

| E355 | 1.058 | 580 | 450 | 10 | 580 | 22 | 490 to 630 | 355 | 22 |

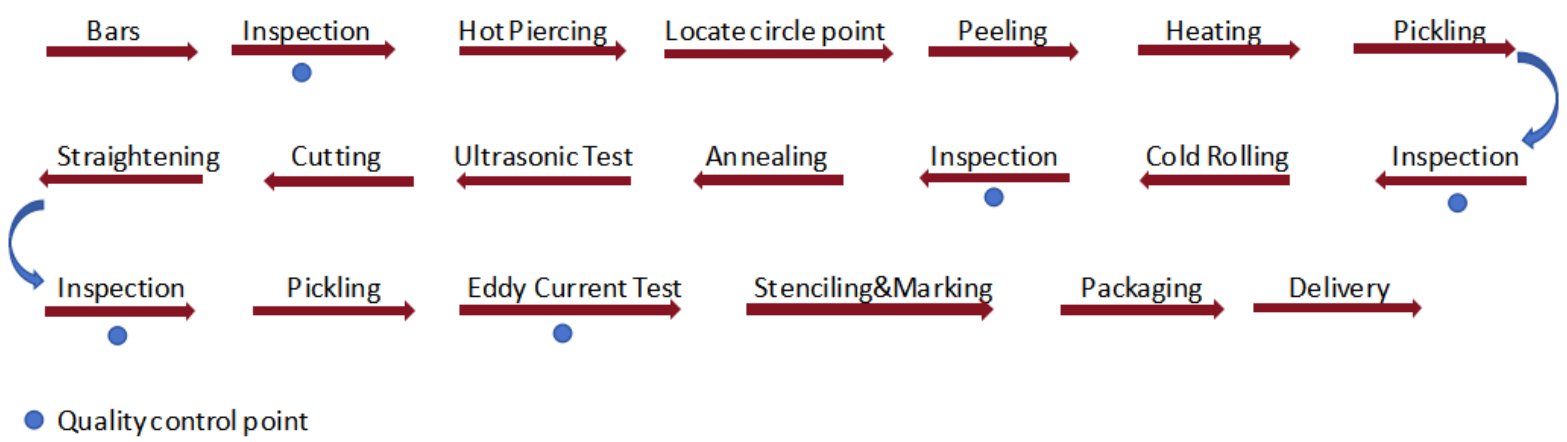

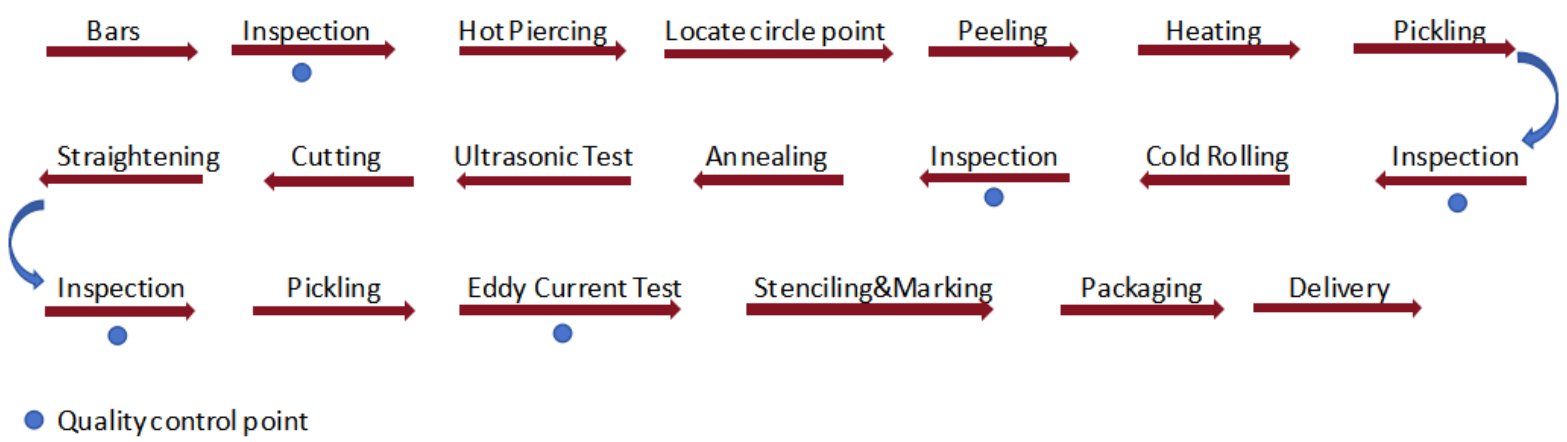

Seamless Steel Pipe Manufacturing Process

The round steel bar is used to produce seamless pipe. After heating the bar to a high temperature, a probe is put into the bar to produce a hole. The cylinder is then moved to rollers that shape it to the required diameter and wall thickness.

Loading and Package